UHRIG Energy

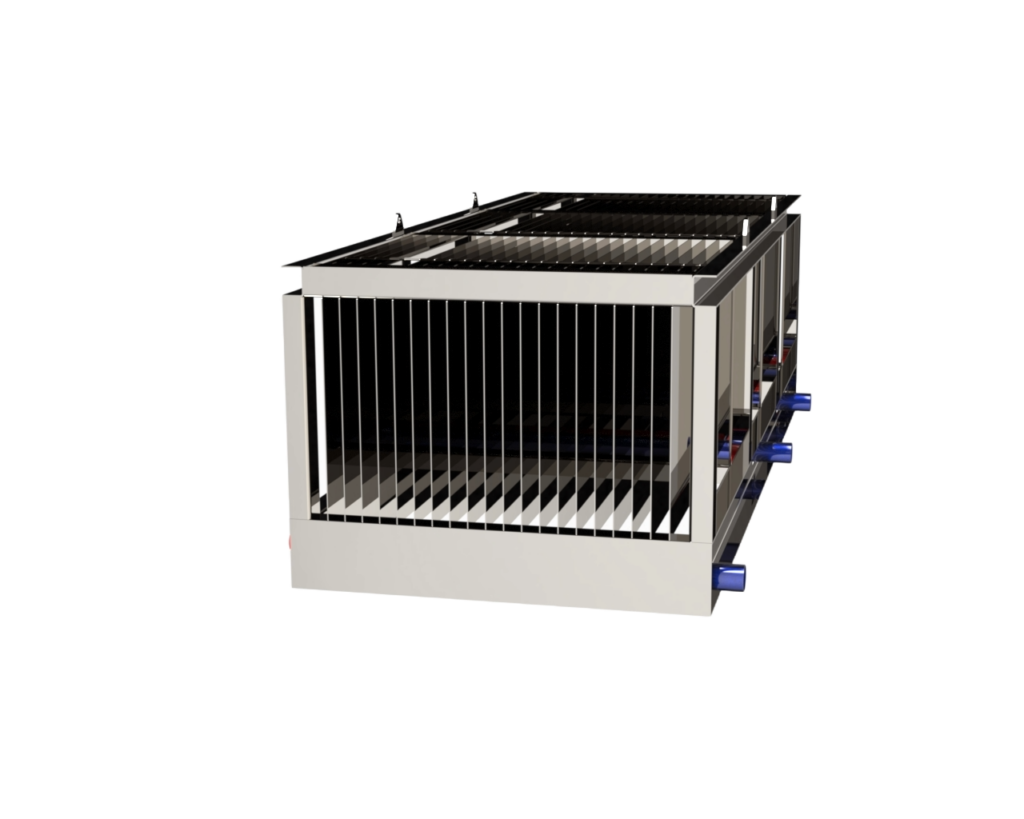

Therm-Liner Stack

The Therm-Liner Stack is used at treatment plants, as a bypass to conventional wastewater pipelines, or in river or lake water projects. The Stack solution is a versatile allrounder that can be used wherever the Therm-Liners A or B are not suitable. The Stack system can be dismantled and removed at the end of its service life.

Are you interested in learning more? Ask us!

Specifications

Scope of application

- Treatment plants, wastewater network, lake and river water

- No restriction to certain pipe diameters

- For remediated and unremediated pipeline infrastructure

Installation

- With or without underground engineering

- Individual installation in or at intrastructure

- Method of attachment depends on conditions on site

Particularities

- Wide range of applications

- Modular extension possible

- Largest heat exchange area per meter

USP

- Special, customizable solution

- Not only for wastewater, but also for lake and river water

- For new, remediated, or unremediated infrastructure

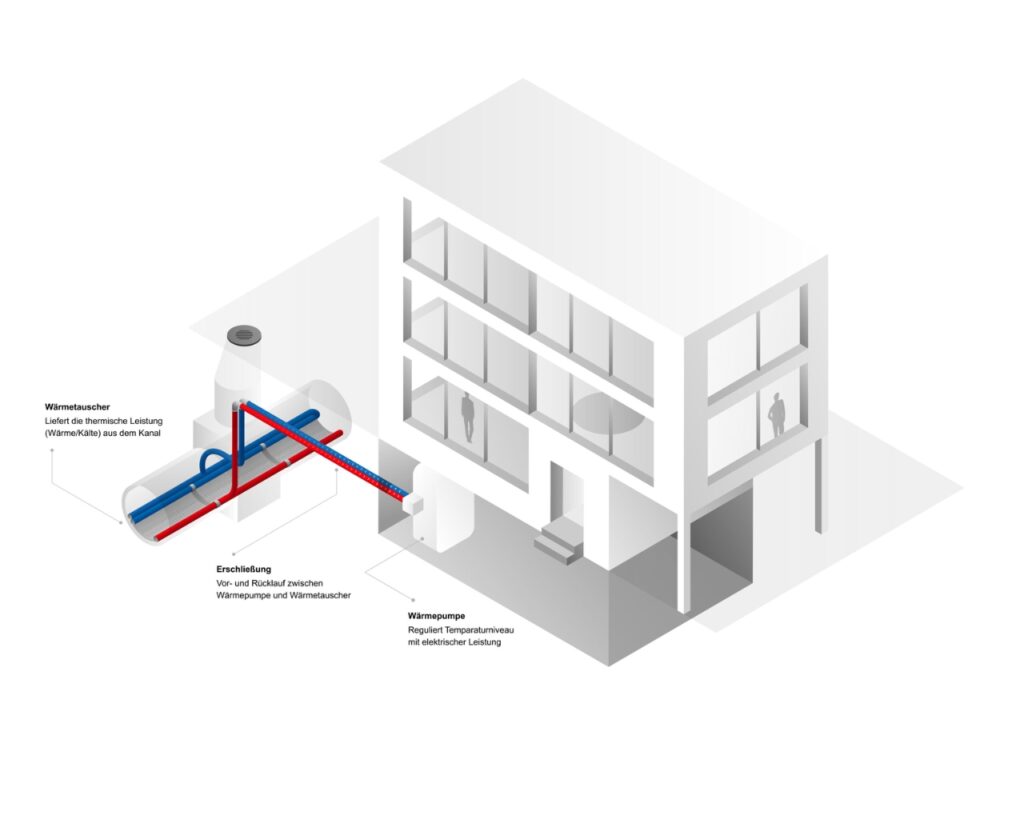

Wastewater heat: components

UHRIG Energy specializes in the ready-to-use construction of heat exchanger systems that connect to the top edge of the pipeline. In order to utilize the thermal energy harvested, it is also necessary to have an interface to the heat pump and the heat pump itself – i.e., three components all together.

- Heat exchanger: delivers the thermal energy from the pipeline

- Interface: flow and return pipes, connection to heat pump

- Heat pump: for regulating the temperature inside the building

For some projects, UHRIG also offers to plan and build the interface. Just talk to us if you’re interested in an all-in-one solution.

Our services

Our goal is to remove barriers and simplify processes for our customers. That is why we provide ready-to-use systems for harvesting energy from wastewater. We:

- plan

- build

- install

- operate and finance

In concrete terms, this means that we not only harvest the heat from the wastewater, but also transport it to the heating center. Once it reaches the heat pump, that is where our customers take over and refine the thermal energy obtained from the wastewater. The heat pump uses electricity to bring the heat to the exact temperature required in the building.

Every project is a custom solution

The wastewater pipelines in Germany have always been different sizes and dimensions. For instance, they could have a circular, oval, or box profile. On top of that, they could be made from any one of a number of possible materials. This is why every wastewater heating project is a custom solution.

After manufacturing our first hundred systems in a factory, we then switched to automated, serial production. Despite this standardization, we can still adapt to the specific situation in each individual pipeline, which is one of our key strengths.

It is this very expertise that makes us able to serve the vastly different framework conditions and requirements in countries other than Germany.